Ventive designs and manufactures the most innovative intelligent building service systems in the UK

Ventive designs and manufactures the most innovative intelligent building service systems in the UK

Innovative Passive Ventilation Systems

Ventive

WINDHIVE®

Combines passive ventilation, heat recovery and system intelligence to deliver 100% fresh air and comfortable temperatures, whatever the weather.

Ventive

ACTIVE

The most efficient wall ventilation and comfort heating & cooling system in the UK. Enhanced PVHR with an innovative heat pump to deliver fresh air and comfort, whatever the weather.

Ventive

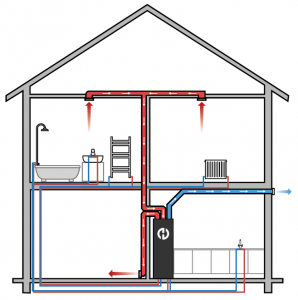

HOME

An integrated home environment management solution, providing ventilation, hot water and comfort; using exhaust air as a source of energy, combined with a high efficiency heat pump and intelligent, connected controls.

Ventive

PASSIVE

A sophisticated passive ventilation system that fits inside a single wall-mounted unit. Intelligent air flows provide free heat recovery with 100% fresh air.